Test Smarter, Profit More: The ROI Secrets of Product Testing

Product testing is more than just a final quality check, it’s a strategic investment that can safeguard your brand, save millions in avoided costs, and unlock significant revenue growth. In today’s competitive landscape, understanding and maximizing the return on investment (ROI) of product testing is essential for ensuring product reliability, customer satisfaction, and overall business success.

What Is ROI in Product Testing?

At its core, ROI is a financial metric used to assess the profitability of an investment. In the realm of product testing, ROI measures the benefits gained, such as improved product quality, reduced warranty claims, and higher customer satisfaction, against the costs incurred in testing. The basic formula for ROI is:

The benefits can be both direct, like increased sales due to a higher-quality product and indirect, such as cost savings from fewer product recalls or reduced support expenses. By quantifying these benefits, companies can justify the investment in rigorous product testing and optimize their quality assurance processes.

Investing in robust product testing programs can yield tremendous returns. Here’s why:

- Enhanced Product Reliability: Thorough testing ensures that products perform as expected in real-world conditions, reducing the risk of defects reaching the market.

- Cost Savings: Early detection of flaws prevents costly recalls, warranty claims, and rework. For instance, in-home usage testing (IHUT) has been credited with transforming product fortunes, P&G’s Febreze, which initially faced a near-zero sales scenario, was reimagined and repositioned after testing revealed consumer insights, eventually becoming a billion-dollar brand (letshighlight.com).

- Customer Satisfaction and Loyalty: Reliable products foster trust, leading to higher customer retention and positive word-of-mouth.

- Regulatory Compliance and Safety: Especially in industries like automotive, electronics, and healthcare, meeting stringent safety standards through rigorous testing can avert legal and reputational risks.

By strategically investing in product testing, companies not only enhance quality but also create a competitive advantage that translates directly into improved financial performance.

Types of Product Testing That Impact ROI

Different testing methods deliver varying returns, depending on the product and market requirements. Some common approaches include:

- Environmental and Stress Testing: Methods like Highly Accelerated Life Testing (HALT) simulate extreme conditions to identify potential failure points early, ensuring that the product can withstand real-world stresses.

- User and In-Home Usage Testing (IHUT): By gathering feedback from actual consumers in their natural environment, companies gain valuable insights into product performance and usability. These insights can drive design improvements that boost market acceptance.

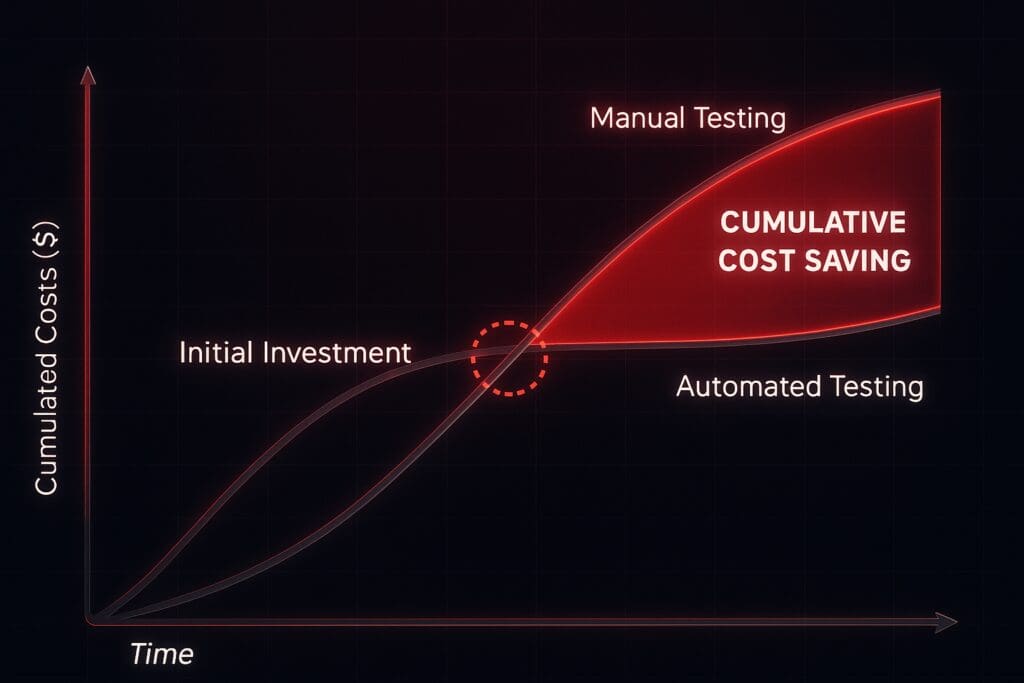

- Automated Testing and Iterative Experimentation: Leveraging automation can significantly reduce testing cycle times while maintaining high accuracy. Recent research into iterative experimentation shows that dynamic, data-driven testing approaches can lead to measurable improvements in key performance metrics (arxiv.org).

Each of these methods contributes to ROI in distinct ways, whether by reducing costs, shortening time-to-market, or driving incremental revenue through better product performance.

Measuring ROI on Product Testing

To calculate the ROI of your testing program, start by defining clear objectives and metrics. Here are a few steps to guide you:

- Set Clear Goals: Identify what you hope to achieve—whether it’s reducing defect rates, shortening the time-to-market, or enhancing customer satisfaction.

- Quantify Costs: Account for all expenses related to testing, including equipment, labor, and any outsourced services.

- Estimate Benefits: Calculate the financial benefits of improved quality. This might include avoided costs from fewer recalls, lower warranty claims, and increased revenue from enhanced customer trust.

- Apply the ROI Formula: Use the standard formula to compute ROI, then compare it against industry benchmarks to gauge the effectiveness of your testing strategy.

KIE Solutions approach to test automation shows that when you measure net cost savings against your testing investment, you can clearly see the financial advantages of a robust testing regime.

Best Practices to Optimize ROI in Product Testing

Achieving a high ROI on product testing requires a strategic approach. Consider these best practices:

- Integrate Testing Early: Incorporate testing throughout the product development lifecycle. Early-stage testing can uncover issues before they escalate, leading to significant cost savings.

- Leverage Automation: Use automated testing tools to accelerate the process and reduce human error. Automated systems not only speed up testing but also enhance consistency and accuracy.

- Adopt Iterative Testing: Instead of one-off tests, adopt an iterative approach that continually refines product performance based on real-time feedback. Research indicates that iterative experimentation can lead to substantial improvements in key performance metrics (arxiv.org).

- Collaborate Across Teams: Engage cross-functional teams in testing efforts. Collaboration between engineers, quality assurance, and product managers ensures that insights are effectively translated into design improvements.

- Utilize Data Analytics: Implement robust data collection and analysis systems to monitor test outcomes, identify trends, and adjust strategies accordingly.

By following these practices, you can maximize the financial benefits of your testing program while maintaining high product quality and customer satisfaction.

ROI on product testing isn’t merely an abstract metric, it’s a tangible measure of how effective testing strategies can drive business success. By ensuring that products meet quality and safety standards, companies can avoid costly recalls, enhance customer satisfaction, and secure a competitive edge in the market. Whether through rigorous environmental testing, user-centered in-home evaluations, or advanced automated testing systems, every dollar invested in product testing has the potential to yield significant returns.

Integrating automation into End-of-Line (EOL) testing significantly enhances the effectiveness of quality assurance processes. Automated EOL systems can perform rapid, consistent, and precise tests, reducing human error and increasing throughput. They enable real-time data collection and analysis, facilitating immediate feedback and adjustments in the manufacturing process. Moreover, automation allows for the implementation of complex testing procedures that might be impractical manually, ensuring comprehensive product evaluation. This leads to improved product reliability, customer satisfaction, and a stronger return on investment. These upgrade can lead to a higher level of efficency on the production floor and in turn create greater profits. Read The C-Suite’s Playbook for Cost-Effective Quality Assurance to see a more in-depth look into this.

KIE Solution specializes in designing and implementing customized EOL test cells tailored to specific manufacturing needs. Their approach involves a thorough analysis of existing processes to develop solutions that maximize efficiency and minimize downtime. KIE Solution’s test cells are built to withstand demanding environments, featuring user-friendly interfaces and easy maintenance. Additionally, they offer advanced services like predictive maintenance and custom factory database design, ensuring long-term operational excellence. By partnering with KIE Solution, manufacturers can achieve reliable, scalable, and future-proof EOL testing systems.