Automation Systems for Milwaukee, WI

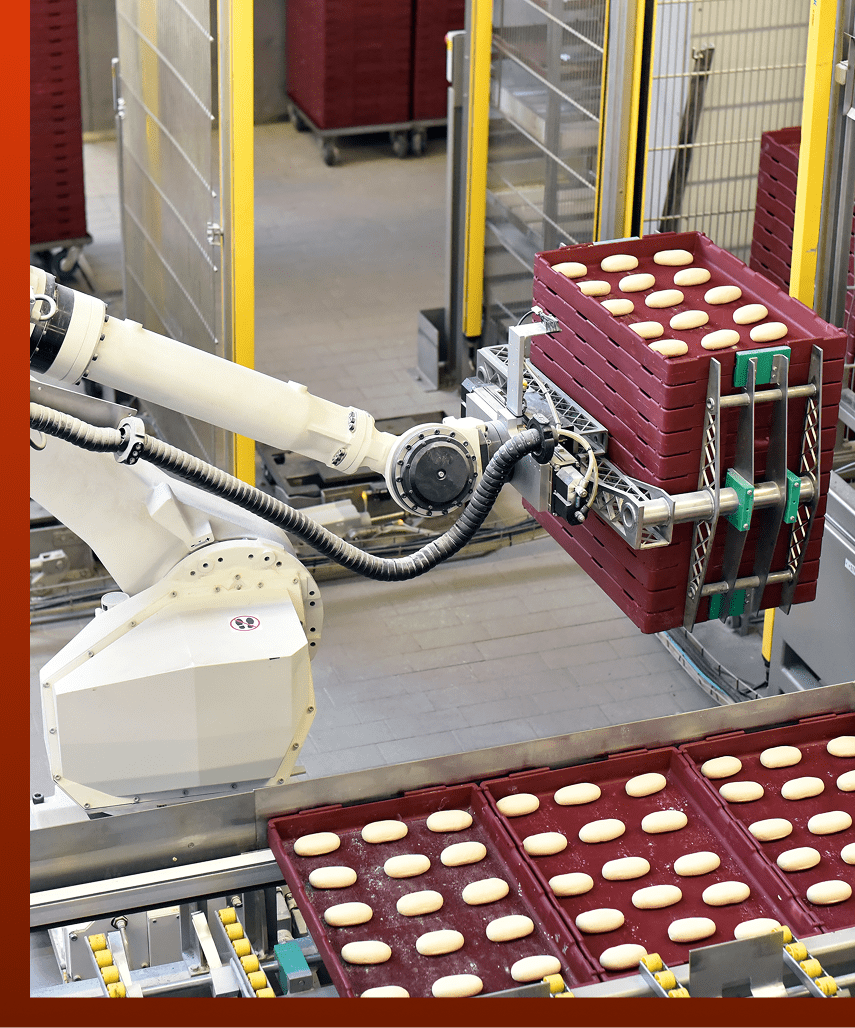

We believe that every manufacturer has unique requirements. Off-the-shelf automation systems can’t always meet those needs. That’s why we specialize in creating custom-built automation solutions designed specifically for your process.

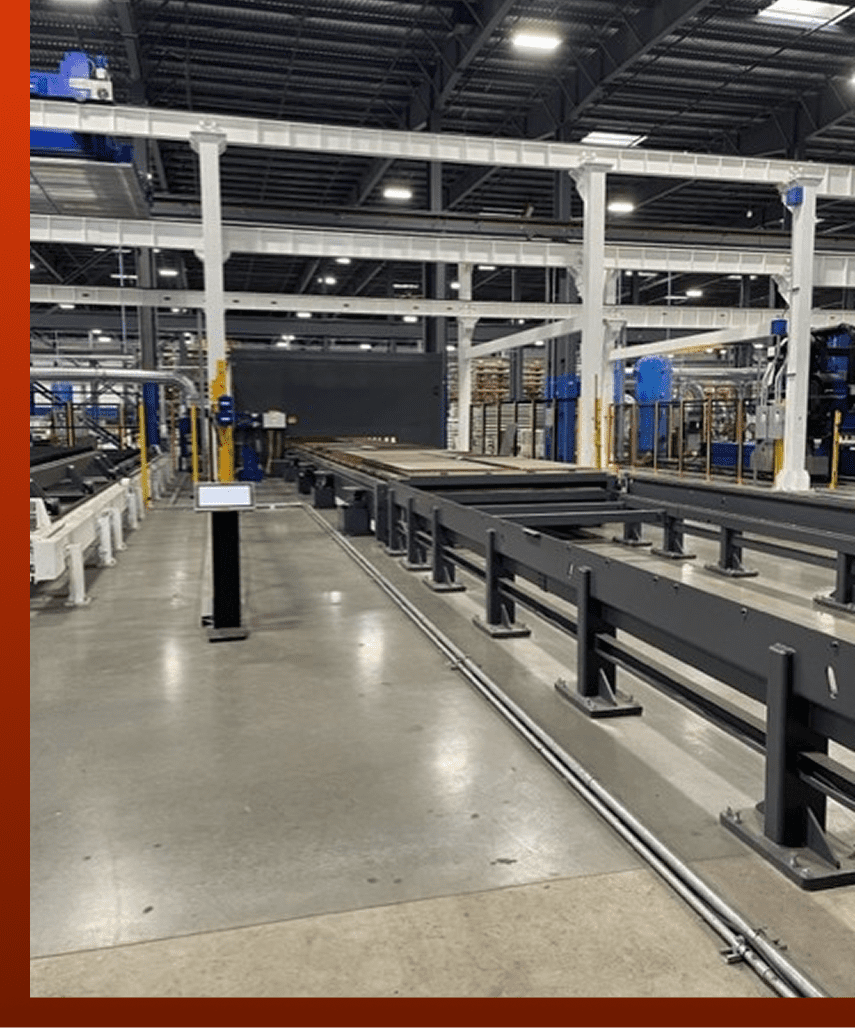

KIE Solution designs and builds advanced automation systems tailored to the needs of manufacturers in the metal and plastic fabrication industries. Serving Milwaukee, WI, we are experts in developing high-performance, custom solutions that address your facility’s unique operational challenges. Unlike off-the-shelf systems, our machines are engineered to fit your exact workflow, ensuring superior efficiency, reduced downtime, and long-term reliability.

Factory Automation That Solves Real Problems

Our factory automation services go beyond standard integration. We take a hands-on approach, sending our experienced engineers onsite to evaluate your current setup, identify bottlenecks, and develop automation strategies that streamline operations. From material handling and assembly automation to End-of-Line (EOL) test cells, our systems are designed to maximize throughput and withstand the toughest industrial environments.

Heavy-Duty Machines With Smart Features

KIE Solution delivers robust machinery built to last. Each system includes intuitive human-machine interface (HMI) screens, clearly defined alarms, and easy-to-replace components, making them not only powerful but also user-friendly. These features help reduce training time and improve operator confidence, all while ensuring consistent, high-quality output.

Predictive Maintenance and Data Integration

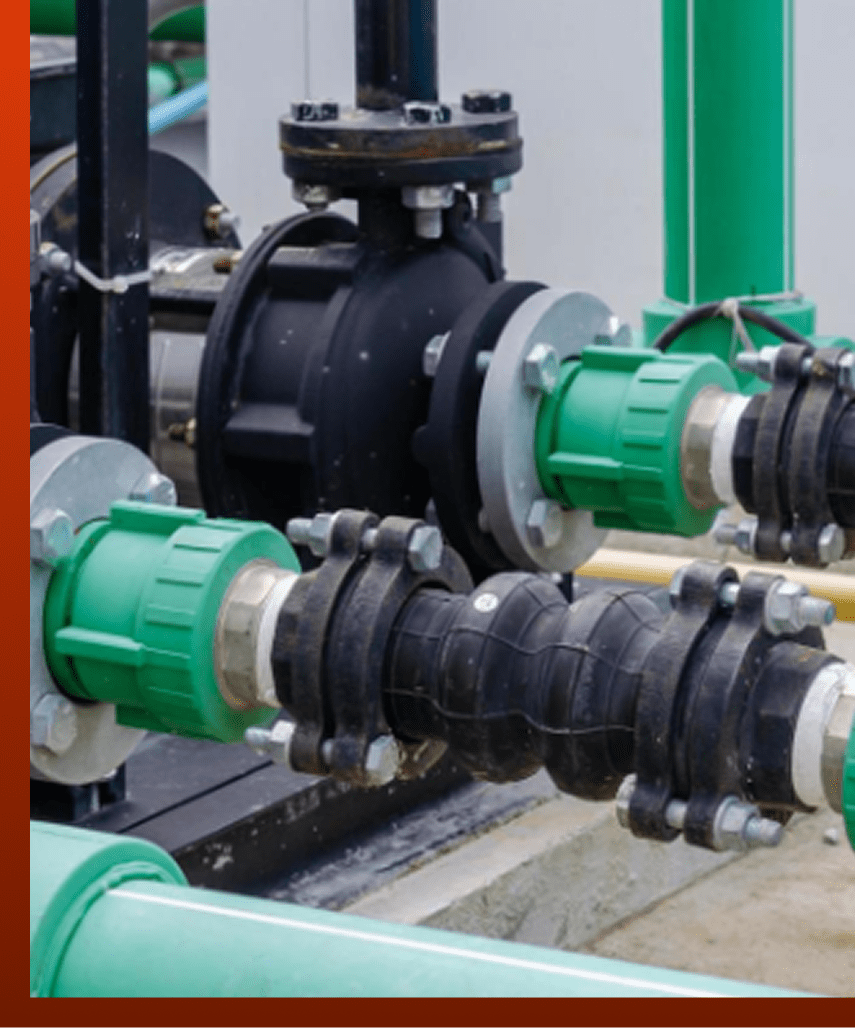

We enhance performance and minimize downtime with advanced predictive maintenance using IntraVue Insight. This technology monitors system health, detects anomalies early, and prevents costly equipment failures. Additionally, our custom database development through Dataforge gives clients actionable insights and full visibility into production processes, allowing smarter decision-making and improved ROI.

Expert Support From Start to Finish

At KIE Solution, we don’t just install automation systems—we support them for life. Our team provides ongoing training, post-installation service, and system upgrades as your business grows. We are dedicated to long-term partnerships, ensuring your system remains efficient, scalable, and aligned with your evolving needs.

If you're looking to elevate your operations with reliable factory automation offered by KIE Solution in Milwaukee, WI, now is the time. Contact us today to schedule a consultation and discover how our custom automation systems can transform your productivity.

Why Custom Automation Matters

Unlike standard solutions from the factory or other integrators, our automation systems are built with flexibility and long-term success in mind. Here's how we do it differently:

Tailored for Your Workflow

Custom solutions designed to fit your specific needs, ensuring maximum efficiency.

Scalable Systems

Start small and expand as your business grows without costly overhauls. Our automation is built to grow with you.

Profitability With High Variability

We make high-variability manufacturing profitable by integrating new technology that adapts to diverse production needs.

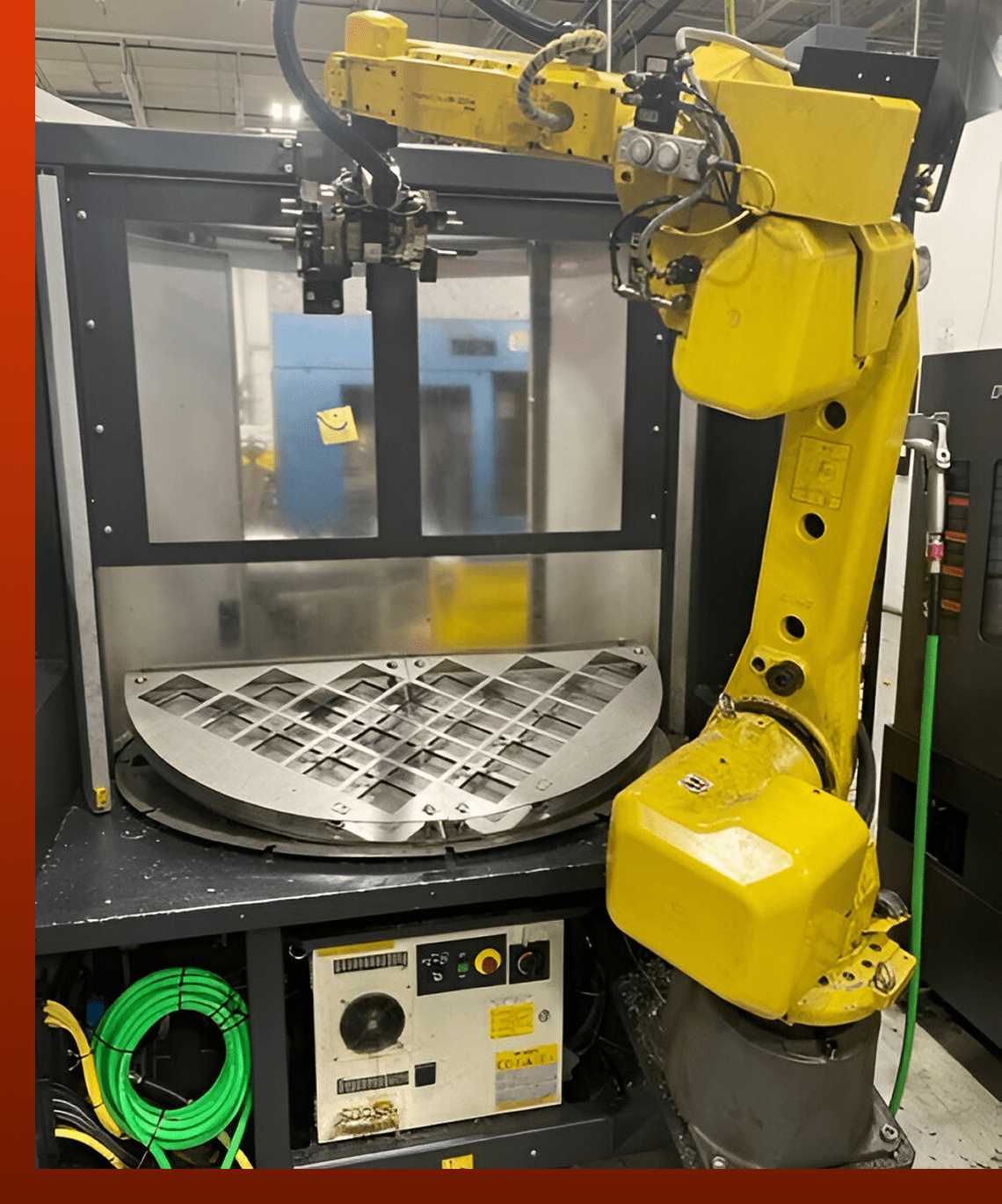

Custom End of Line Testing (EOL)

Advantages of Custom End-Of-Line Testing with KIE Solution

1. Customizable Interface

- KIE Solution designs End-Of-Line (EOL) test cells with a user-friendly, fully customizable interface.

- Operators can easily adjust test parameters, monitor real-time data, and configure reporting features to match specific production requirements.

- The interface is designed to simplify operation and minimize training time, improving overall efficiency.

2. Specialized Combination of PLC and Data Analysis Computing Power

- KIE Solution integrates high-performance PLCs with advanced data analysis computing power.

- This combination allows for real-time monitoring, rapid processing of test data, and immediate feedback to operators and production systems.

- The system can handle complex testing requirements, including multiple inputs and outputs, with low latency.

3. High-Frequency Data Sampling (Up to 100,000 KHz)

- KIE Solution’s EOL test cells are capable of sampling data at up to 100,000 KHz, providing high-resolution insights into product performance.

- This allows for precise detection of product defects, performance variations, and early identification of potential failures.

- High-frequency sampling ensures that even the smallest inconsistencies are captured and addressed promptly.

4. Scalable and Flexible Design

- KIE Solution’s EOL test cells are built to accommodate a wide range of products and production volumes.

- The modular design makes it easy to update or modify the testing process as production requirements change.

- This scalability ensures that the system remains relevant and efficient as the business grows.

5. Integrated Reporting and Traceability

- The system generates detailed test reports and logs for full traceability.

- Data is stored in a centralized database, making it easy to track performance trends and troubleshoot issues.

- Integrated reporting helps improve quality control and supports continuous improvement efforts.

Intelligent Monitoring & Data Management

By integrating IntraVue Insight, our predictive maintenance system, we continuously monitor the health of your network and equipment. This helps prevent costly downtime and ensures that your operations run smoothly.

Operator-Centric Design

Many solutions overlook the people who will operate them, but at KIE Solution, we prioritize ease of use for your team.

Intuitive HMIs

Simple, clear interfaces that reduce the learning curve for operators.

Easy Troubleshooting

Our systems come with clear alarm systems and easy-to-access maintenance features, ensuring operators can resolve issues with minimal training.

Focused on Efficiency

Streamlined controls and systems that make your operators more effective, not less.

On-Site Engineering & Support

Our team of engineers works on-site to ensure seamless integration, installation, and training. We also provide ongoing support to ensure your system remains efficient over time.

True Integration

Our engineers understand your specific challenges and help integrate systems smoothly into your process.

Comprehensive Training

We ensure your team is fully trained to operate and maintain the system, reducing the learning curve.

Long-Term Maintenance

We offer continuous support to keep your systems running efficiently over time.

Let’s Build the Perfect System Together

Whether you need a custom-built system, real-time monitoring, or long-term support, we’re here to help.